Tips for Maximizing Bathroom Space with Anti Slip and Safety First Designs

Maintaining Safety Through Careful Material Selection and Installation

Ensuring Equipment Functionality

Regular maintenance and inspections of all equipment play a pivotal role in accident prevention. This hands-on strategy guarantees that machinery runs smoothly and safely, cutting down the chances of unexpected failures or operational hiccups. Well-maintained equipment not only safeguards workers but also preserves the surrounding environment. Routine checks should cover lubrication, bolt tightening, and thorough visual inspections for signs of wear or damage.

Neglecting equipment upkeep can trigger severe consequences, including sudden breakdowns, employee injuries, and costly property damage. A robust maintenance plan—aligned with manufacturer guidelines and executed by qualified technicians—forms the backbone of any effective safety initiative.

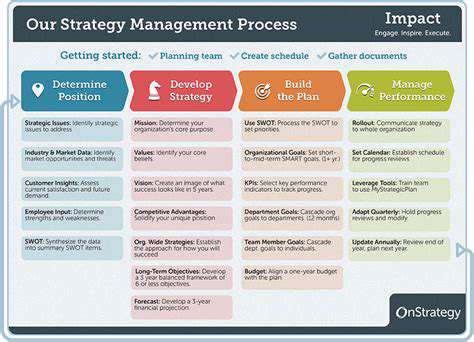

Implementing Safe Work Practices

Every workplace needs crystal-clear safety protocols that are strictly enforced. These guidelines must detail procedures for hazardous material handling, machinery operation, and emergency responses. Comprehensive training ensures staff fully grasp potential risks and know exactly how to avoid them. Safety programs should evolve alongside procedural updates or equipment changes.

When safety rules become second nature, they transform workplace culture. Employees develop a watchful eye for hazards and feel comfortable reporting concerns—creating a safer environment for everyone.

Creating a Safe Working Environment

A tidy, well-organized workspace isn't just about appearances—it's a critical safety factor. Clutter creates trip hazards and can lead to preventable accidents. Dedicated storage zones and proper waste disposal systems are game-changers for maintaining order. These measures protect workers while ensuring materials don't vanish into potential danger zones.

Addressing Potential Hazards

Proactive hazard assessments should be standard practice, systematically scanning for risks before they cause harm. Detailed records of identified dangers pave the way for targeted solutions. Evaluations should cover everything from slip-and-fall risks to exposure to dangerous substances—stopping accidents before they start.

Action is everything when hazards are spotted. Solutions might include new safety gear, revised work methods, or specialized training. Prompt hazard resolution dramatically lowers accident rates, fostering a workspace where productivity and safety go hand in hand.

Read more about Tips for Maximizing Bathroom Space with Anti Slip and Safety First Designs

Hot Recommendations

- Trendy Kitchen Interiors: Open Concepts and Smart Storage Solutions

- Expert Multi Functional Room Ideas for Combining Entertainment with Fitness

- Modern Home Office Inspirations for a Study That Merges Work and Leisure

- Modern Bathroom Design Ideas for Optimizing Small Spaces and Safety

- Expert Strategies for a Children's Room That Inspires Growth and Imagination

- Modern Bathroom Inspirations for a Space That Prioritizes Safety and Efficiency

- Creative Multi Functional Space Ideas for a Room That Combines Gym and Media

- Modern Techniques for a Multi Purpose Room That Enhances Home Entertainment and Fitness

- Expert Guide to Balancing Modern Art and Functional Living Room Layouts

- Expert Tips for a Children's Room That Balances Play, Learning, and Security